MetaL Mesh

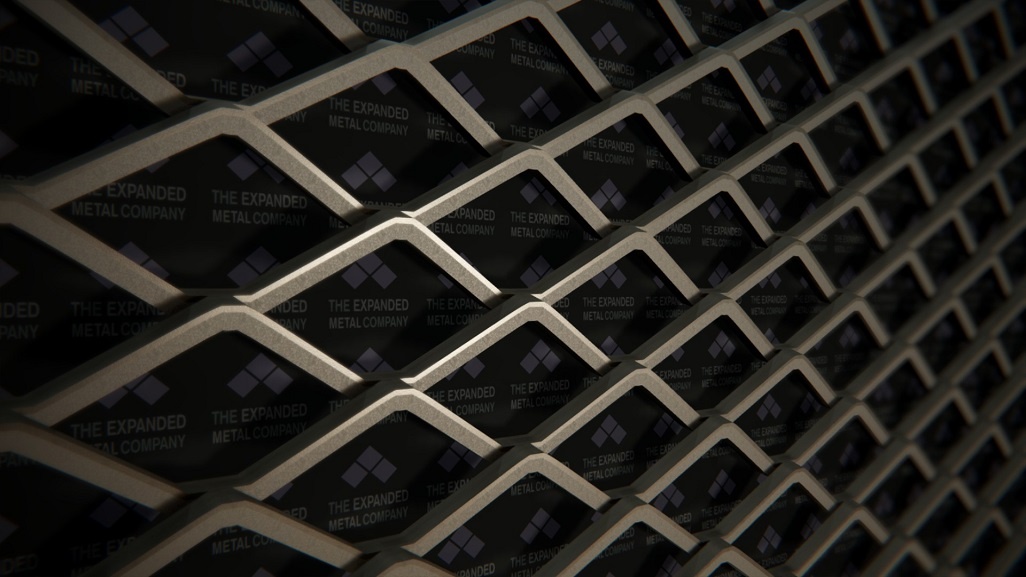

- Expanded Metal Mesh

- Gratings and Stair Treads

- Gabions

- Handrailing & Stanchions

- Perforated Metal

- Weldmesh

- Zinga

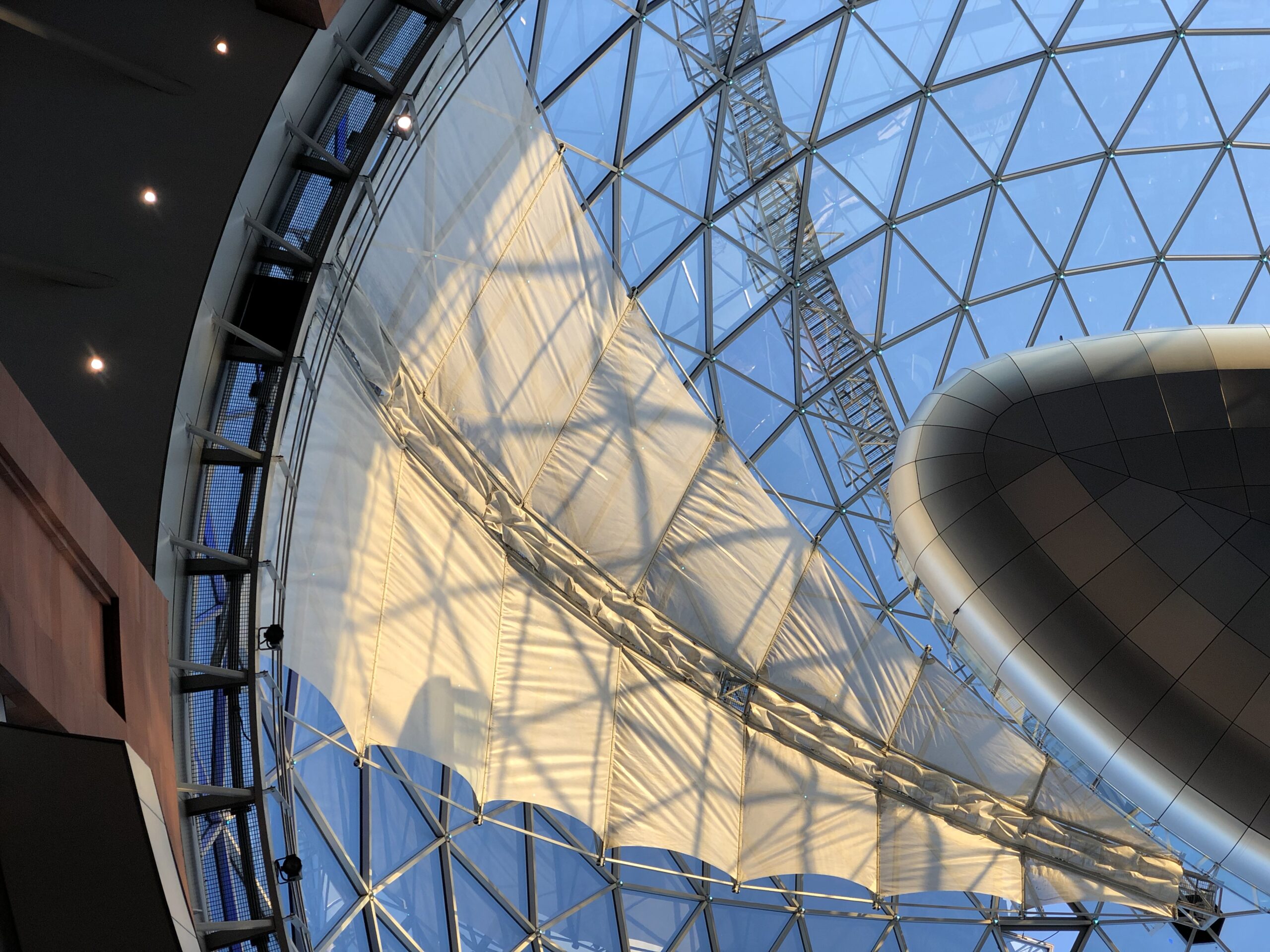

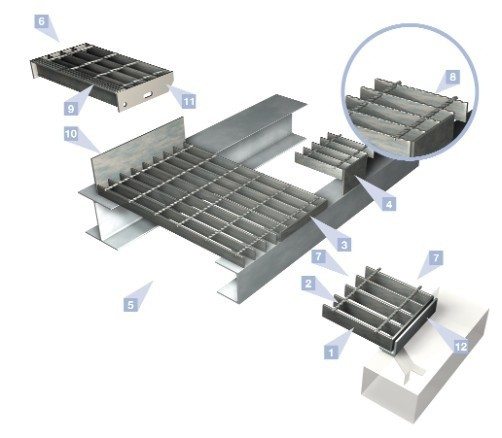

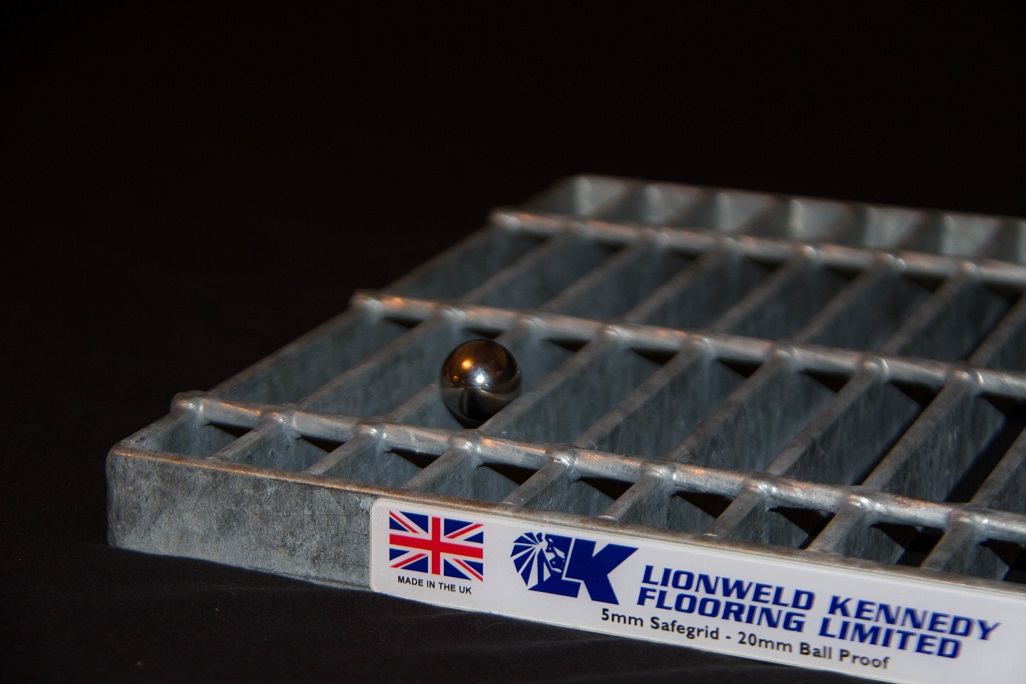

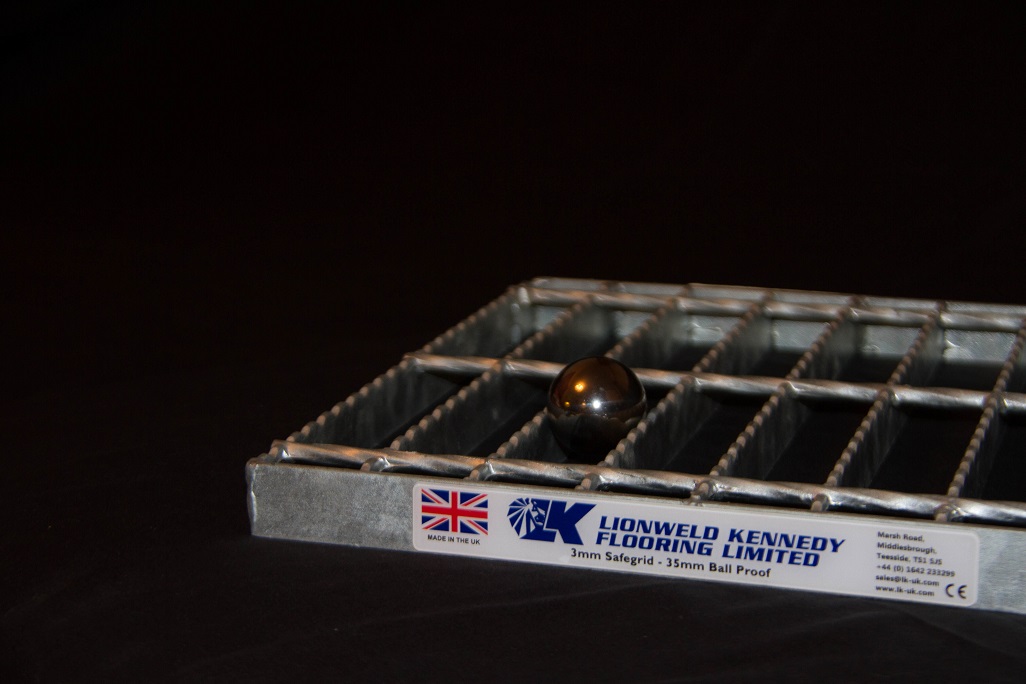

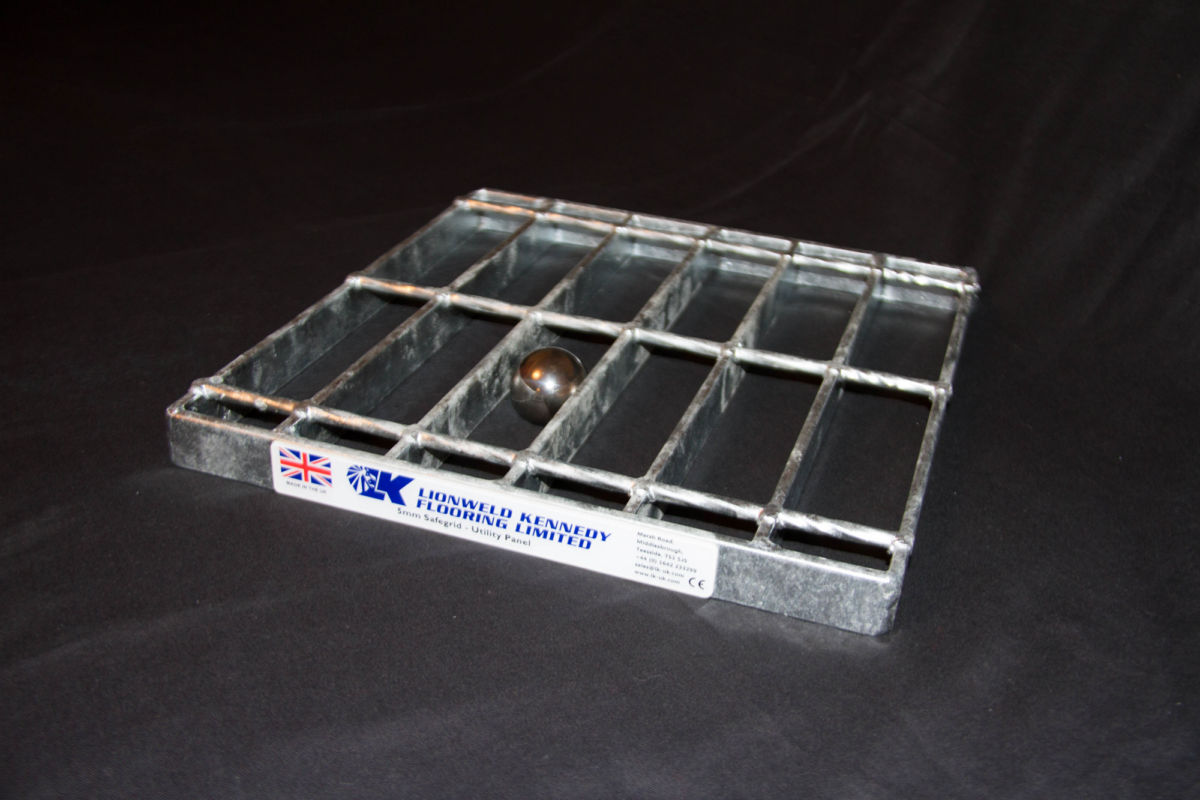

gratings and stair treads

Suitable for a wide range of applications including mezzanines, walkways, platforms, stairways, landings, gantries, offshore, oil & gas industry and more.

more

GABIONS

Wire mesh crates with stones or soil gabions stacked or placed in specific patterns to create eco-friendly barriers, walls and structures for engineering and construction projects.

more

handrailing & stanchions

Industrial handrail systems designed to meet the unique needs of your facility. Erected/dismantled in small sections and versatile to suit all applications.

more

perforated metal

Unique designs, combine strength and aesthetics, makes it an excellent choice for a wide range of projects.

more

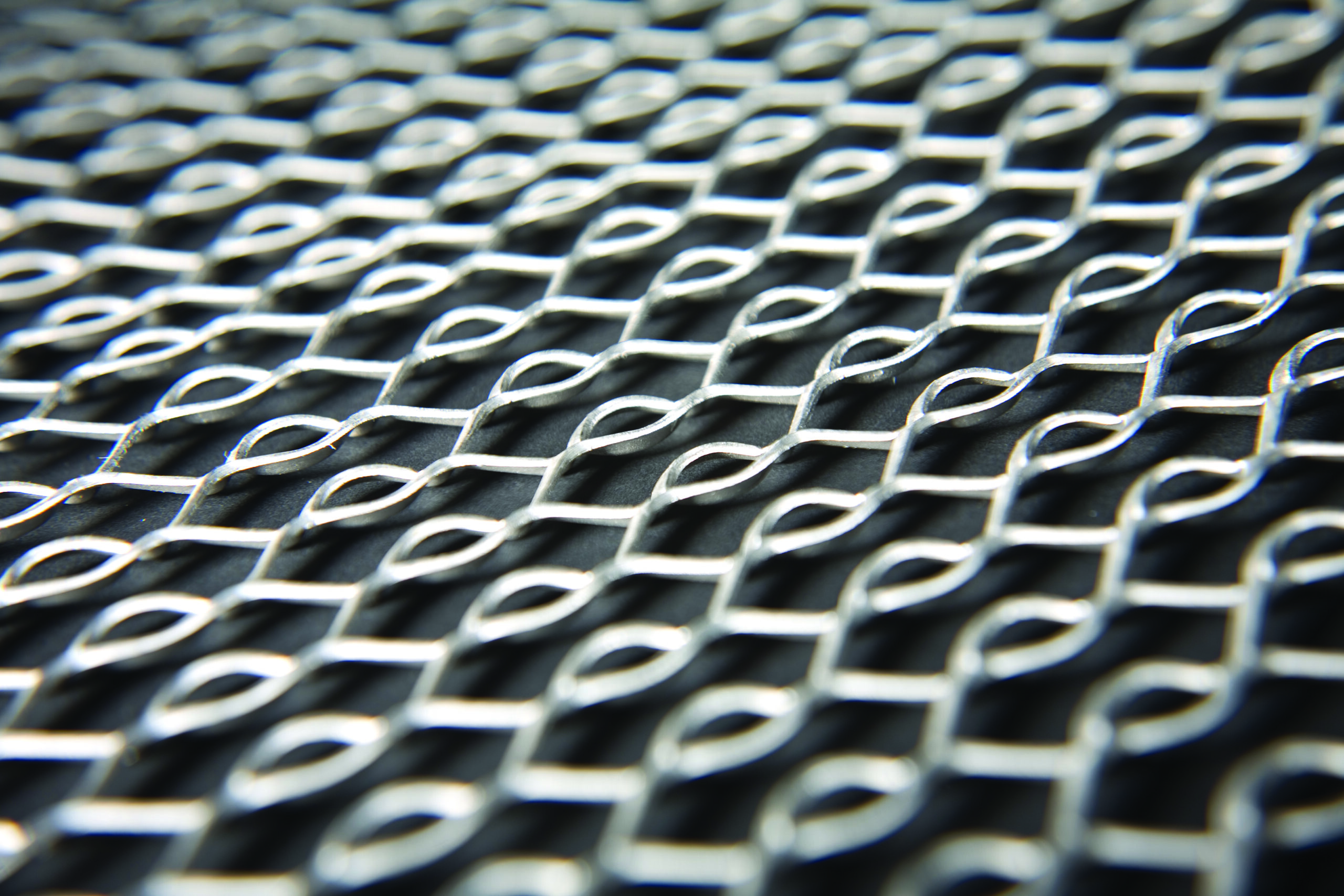

WeldMESH

Welded grid structure provides strength, durability, and stability, making it suitable for a wide range of applications.

more